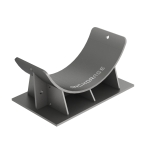

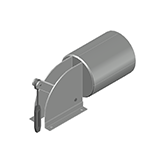

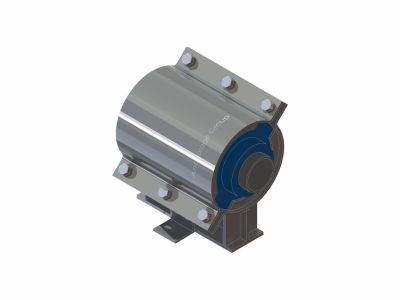

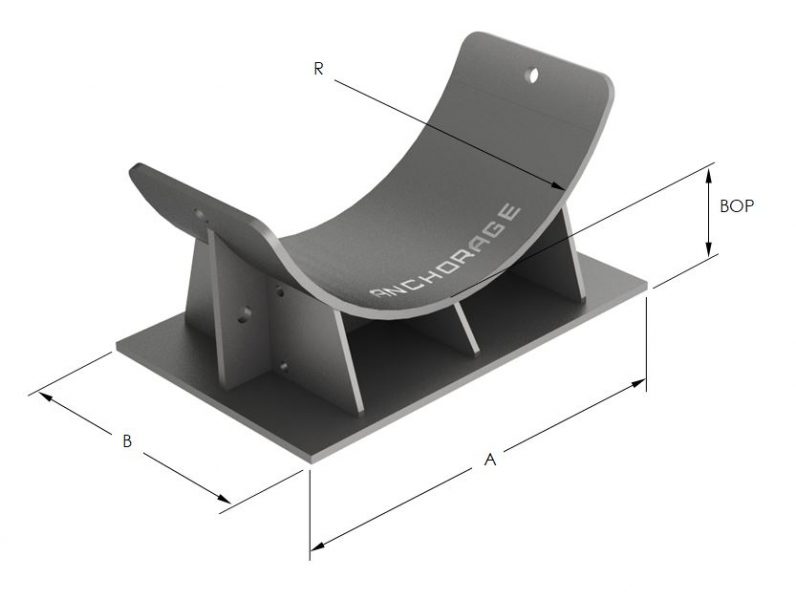

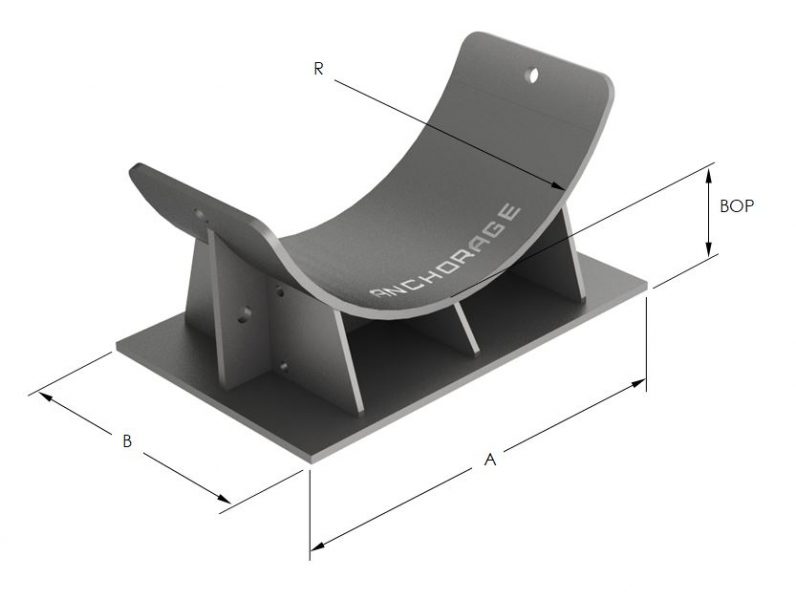

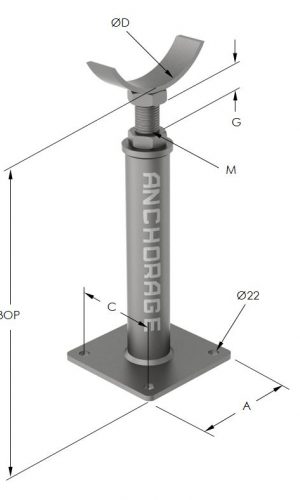

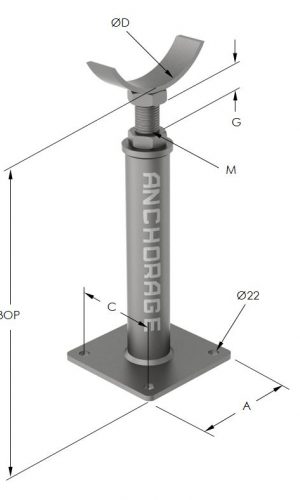

Anchorage Heavy Duty Custom Pipe Cradles were the perfect solution to support a run of 1015mm OD DICL pipe.

The Customer:

A leading Civil & Drainage contractor on a Mine Site in the Hunter Valley.

The Challenge:

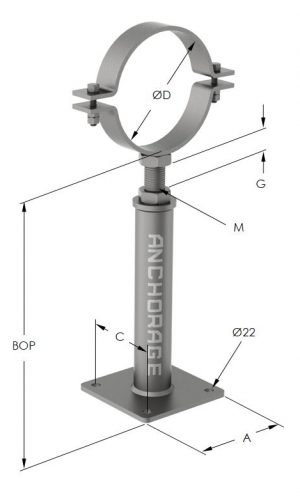

In a tight construction time-frame, a large pipe had to be installed as part of a dam upgrade. The pipe was a non-standard size, and needed to be installed quickly and precisely. Due to rain, the project had been beset by delays and time was running out. They needed custom pipe cradles to suit the pipe sizes as well as load ratings and engineering certifications.

The Solution:

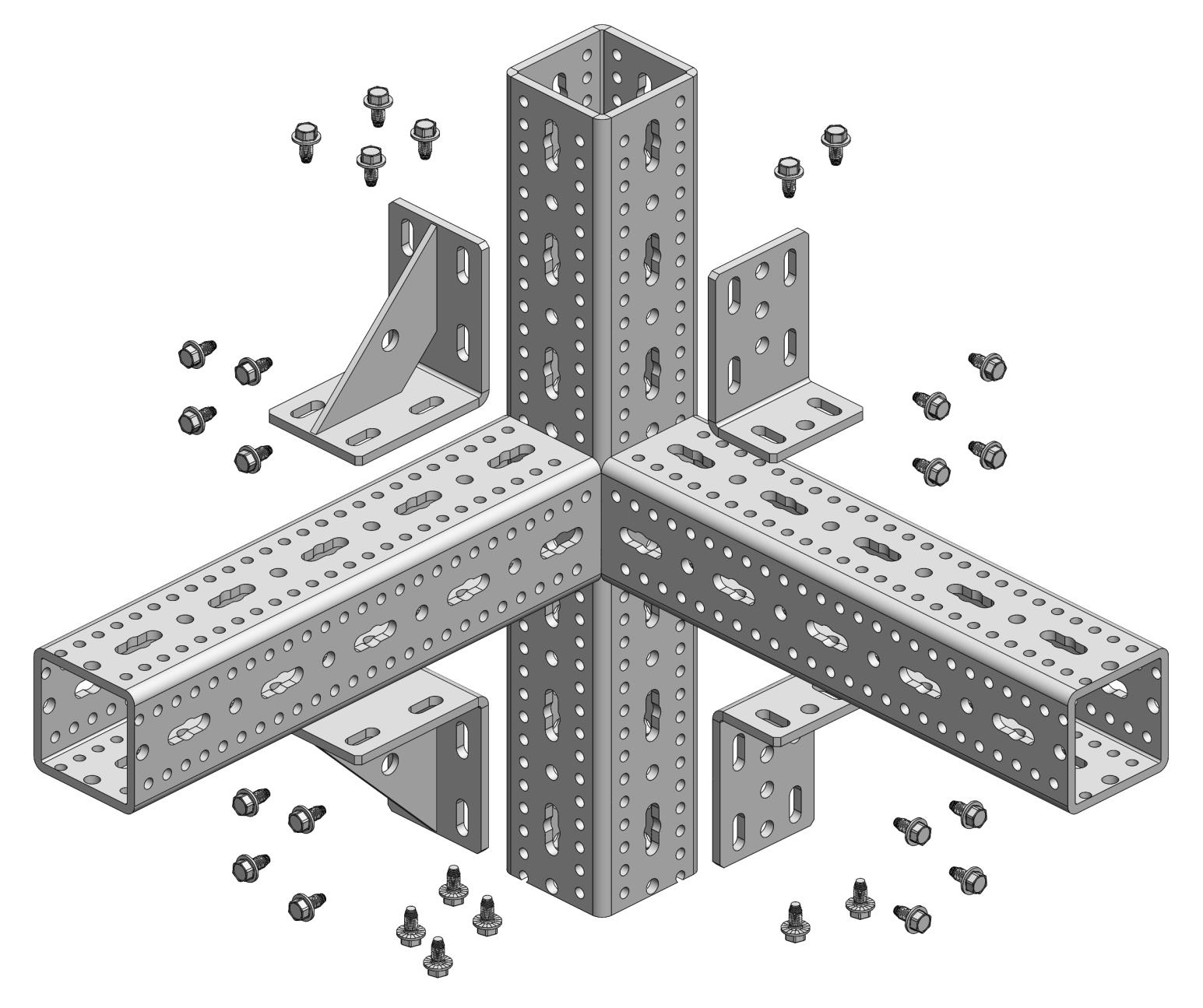

Anchorage Pipe Supports had the ability to manufacture custom sizes and the capacity to provide the necessary specifications and certifications. Furthermore, the Anchorage team were able to mobilize quickly and the customer felt confident that the supports would be delivered on time and exactly to spec.

The Results:

The Anchorage team got to work. Production time was reserved, transport was arranged, material was procured, and drawings finalised. Fabrication commenced as soon as drawings were approved. The supports were dispatched on a specialist delivery truck, for overnight transport to the mine site. Ahead of D-Day for installation of the pipe. The Anchorage supports were installed & pipe placement was competed without a hitch.

The Conclusion:

As a result, the custom, heavy duty pipe cradles supplied by Anchorage Group Pipe Supports provide a durable reinforcement for the pipeline. Anchorage Group’s quick service, reliability and quality product allowed the customer to complete the portion of works to their revised schedule.