- Products

-

-

-

Categories

AG630

AG630HEIGHT ADJUSTABLE SUPPORT - CRADLE MOUNT

AG631

AG631HEIGHT ADJUSTABLE SUPPORT - CLAMP MOUNT

AG632

AG632HEIGHT ADJUSTABLE FLANGE MOUNT

AG634

AG634INSULATED HEIGHT ADJUSTABLE SUPPORT - CRADLE MOUNT

AG636

AG636INSULATED HEIGHT ADJUSTABLE SUPPORT - CLAMP MOUNT

AG100

AG100LIGHT DUTY 2-BOLT PIPE CLAMP

AG110

AG110MEDIUM DUTY 2-BOLT PIPE CLAMP

AG112

AG1122-BOLT CLAMP FOR DICL PIPE

AG115

AG1152-BOLT CLAMP FOR HDPE PIPE

AG120

AG120HEAVY DUTY 2-BOLT PIPE CLAMP

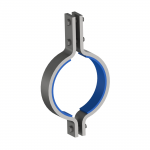

AG130

AG130INSULATED 2-BOLT PIPE CLAMP

AG150

AG150LIGHT DUTY 3-BOLT PIPE CLAMP

AG160

AG160MEDIUM DUTY 3-BOLT PIPE CLAMP

AG170

AG170HEAVY DUTY 3-BOLT PIPE CLAMP

AG190

AG1903-BOLT PIPE CLAMP FOR HIGH TEMPERATURES

AG200

AG200INSULATED 3-BOLT PIPE CLAMP

AG220

AG220LOW TEMPERATURE RISER SUPPORT

AG250

AG250CLEVIS CLAMP

AG550

AG550HEAVY DUTY PIPE CRADLE

AG560

AG560CLAMPED PIPE SHOE

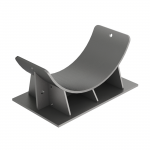

AG565

AG565SINGLE PIPE SHOE

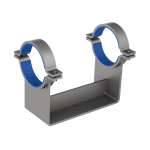

AG570

AG570DOUBLE PIPE SHOE

AG580

AG580WELD-ON PIPE SHOE

AG585

AG585INSULATED SINGLE PIPE SHOE

AG590

AG590INSULATED DOUBLE PIPE SHOE

AG595

AG595INSULATED CLAMPED PIPE SHOE AG595

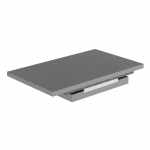

AG620

AG620SLIDE PLATE

AG412

AG412SADDLE CLAMP FOR DICL PIPE

AG415

AG415SADDLE CLAMP FOR HDPE PIPE

AG420

AG420SADDLE GUIDE

AG430

AG430SADDLE CLAMP

AG440

AG440INSULATED SADDLE CLAMP

AG445

AG445INSULATED SADDLE GUIDE

AG470

AG470U-BOLT PIPE GUIDE

AG475

AG475U-BOLT GUIDE FOR HDPE PIPE

AG480

AG480U-BOLT PIPE CLAMP

AG485

AG485U-BOLT CLAMP FOR HDPE PIPE

AG490

AG490INSULATED U-BOLT PIPE CLAMP

AG495

AG495INSULATED U-BOLT CLAMP FOR HDPE PIPE

AG510

AG510INSULATED U-BOLT GUIDE

AG515

AG515INSULATED U-BOLT GUIDE FOR HDPE PIPE

AG530

AG530TEFLON INSULATED U-BOLT GUIDE

AG260

AG260BEAM CLAMP

AG270

AG270FULLY THREADED ROD

AG280

AG280DROP ROD RH/LH

AG290

AG290FORGED WELDLESS EYE NUT

AG295

AG295SPADE NUT

AG310

AG310HEX CONNECTOR / COUPLER NUT

AG320

AG320FORGED CLEVIS & PIN

AG330

AG330FORGED TURNBUCKLE

AG340

AG340PIPE LUG

AG350

AG350WELDED LUG

AG360

AG360WELDED BEAM ATTACHMENT

AG370

AG370WELDED BEAM ATTACHMENT WITH LOAD PIN

AG385

AG385HEMISPHERICAL CUP & WASHER

-

-

-

- About

- Projects

- Resources

- Contact